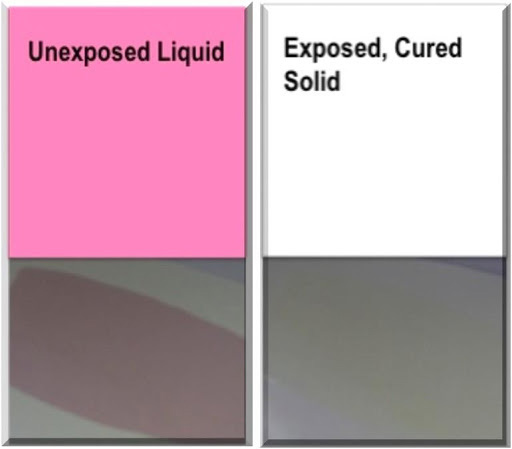

UV curable coatings and adhesives are becoming more popular due to the numerous benefits that UV technology has to offer. Although one of the advantages of UV technology is the fast cure process, if the coating or adhesive is completely clear, it is difficult to determine if the whole surface has been exposed to light and therefore cured.

One approach to overcome this issue is the use of a cure indicator. Depending on the application, the cure indicator can start as one color and change to another, go from colored to transparent, or become colored as the cure process (through light exposure) takes place.

Some of the critical features of a good cure indicator include:

- Long time color stability once incorporated into the formulation

- Long hours of color stability (no fading) after the coating/adhesive has been applied (this usually applies to indoor lighting conditions)

- Ease of incorporation into formulations

- Low levels of addition that still allows for easy-to-see color

- Complete and irreversible color change under UV irradiation

Our line of color change indicators has been designed with the above performance in mind. As a result, we can offer 4 different color change concentrates that have been tested in both 100% solids and water based formulations.

Due to the differences in chemistry, their performance is highly dependent on the formulation. At the moment we offer 3 different colors: blue-to-clear, red-to-clear and violet-to-clear.

Although these color change concentrates were initially developed for on-site floor coating applications, they can be used virtually in any radiation curable application.

For more information, samples, and prices, click here