For a new technology to be successful in a well-established market, not only the benefits have to outgrow those of the traditional technology but also needs to provide competitive pricing and exceptional performance.

In the beginning, UV (radiation) cure technology was only utilized at industrial level. As any new emerging technology, equipment price was high, and the technology was not well understood by all parties involved. Over the years, UV technology has evolved to the point that now is accessible to applications that are closer to the everyday customer (for example, UV floor coatings, UV nails, just to name a few), equipment is economically more accessible to smaller companies and the benefits of the technology are better understood.

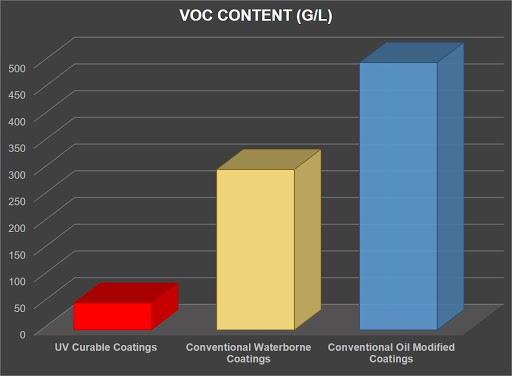

- UV Curing is a “green technology”: No organic solvents or volatile organic compounds (VOC), which means zero emissions of toxic gases and harmful chemicals

- Radiation cure provides a fast cure, i.e., faster turnaround. No need for drying ovens or waiting hours or days for the cure process to take place. As soon as the material is irradiated with light, the curing starts and it is done in a matter of seconds! Your product is ready to use!

- UV cured materials possess better properties. From adhesion to scratch and chemical resistance.

- Radiation curable formulations are either 100% solids or water based, which means no flammable or hazardous materials involved.

- Overall smaller footprint for equipment = overall cost savings.

- Although you might pay more of a premium price for your formulation upfront, often you require to use less of it since there is no evaporation of solvent: the thickness you apply is the thickness that you dry to. Again, overall cost savings.

The benefits of UV technology are endless. It is not only more economical in the long run for companies but it is also better for the environment and the workers that have to handle these formulations.