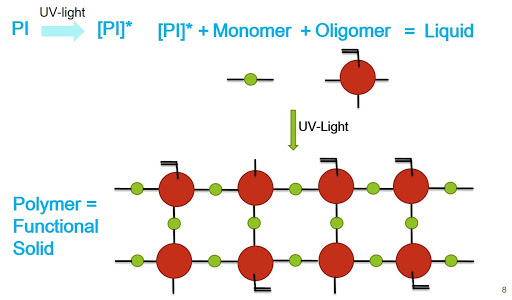

The radiation cure process describes the use of light to trigger the formation of a solid polymer from a mixture containing monomers, oligomers, photoinitiators and additives. A wide variety of properties can be achieved by modifying the components of the formulations and the final photopolymer can be used in applications ranging from coatings,adhesives, inks, 3D printed parts to name a few.

Every component in the formulation has a critical function, and therefore, knowing the desired properties of the final product is critical to choose the right components. Oligomers, for example, are the components responsible for the overall properties of the cured polymer (hardness, flexibility, scratch resistance). Monomers, on the other hand, serve as a diluents (regulates viscosity) and crosslinkers, while photoinitiators are the small molecules responsible for light absorption and generation of the active species that will trigger the crosslinking. And finally the additives help to fine tune the performance of the photopolymer.

Light source selection is a key component as a well. A mismatch between formulation and light source will result in a failed cured or poor cure (gel-like consistency rather than a solid photopolymer).

In order to produce a successful UV/Visible light curable formulation all components must be considered as a whole unit rather than individual parts. With capabilities that range from R&D to large scale manufacturing, Spectra Photopolymers has the tools to become your photopolymer supplier. Contact us for more information.